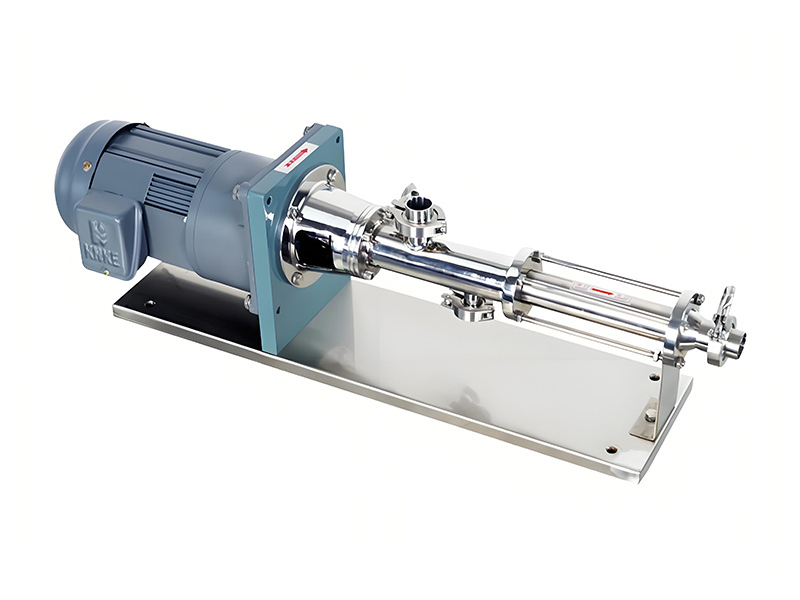

The Single-stage dosing screw pump is a high-precision positive displacement pump designed for accurate metering and dosing of low- to high-viscosity liquids. Based on the principle of the Progressive cavity pump, it offers stable, pulsation-free flow and exceptional dosing accuracy, making it an ideal solution for chemical dosing, wastewater treatment, food processing, and other industries where controlled and consistent liquid transfer is critical.

Unlike centrifugal or diaphragm pumps, the single-stage dosing screw pump delivers constant flow rates independent of pressure fluctuations, ensuring high repeatability and smooth operation. Its compact structure integrates a single-stage rotor-stator assembly that maintains uniform flow with minimal shear, preventing damage to sensitive fluids or emulsions.

Made from high-quality stainless steel (SS304 or SS316L) and corrosion-resistant elastomers, this pump is suitable for aggressive chemical media, slurries, and viscous solutions. Its simple structure, low maintenance requirements, and long service life make it a preferred choice for precision dosing applications in modern process industries.

High Dosing Precision:

The single-stage design ensures accurate and consistent metering with minimal pulsation, ideal for proportional dosing systems.

Wide Range of Flow Rates:

Capable of handling extremely low to moderate flow rates while maintaining pressure stability, suitable for micro-dosing and continuous feed applications.

Low Shear Operation:

Gentle pumping action preserves the physical and chemical properties of sensitive liquids such as polymers, emulsions, or biological fluids.

Excellent Self-Priming Performance:

Able to self-prime up to 8 meters depending on the fluid characteristics, reducing the need for external priming equipment.

Compact and Space-Saving Design:

The single-stage horizontal configuration simplifies installation and integration into dosing skids, laboratory systems, or industrial automation setups.

Material Flexibility:

Pump materials are customizable for different chemical compatibilities — from standard stainless steel to high-grade 316L for aggressive fluids.

Easy Maintenance:

Modular structure with replaceable stator and rotor parts ensures minimal downtime and simple on-site repair.

High Efficiency and Energy Saving:

Maintains constant volumetric efficiency with low power consumption, ideal for continuous 24/7 operations.

| Parameter | Specification Range |

Model | Single-Stage Dosing Screw Pump (G-Type or Custom) |

Flow Rate | 0.05 m3/h – 10 m3/h (customizable) |

Pressure Range | Up to 0.6 MPa |

Speed | 200 – 1200 rpm |

Viscosity Range | Up to 500,000 cP |

Temperature Range | -20°C to 120°C (optional up to 180°C) |

Material of Construction | SS304, SS316L, Cast Iron, or Duplex Stainless Steel |

Rotor Material | Hardened stainless steel, chrome-plated steel |

Stator Material | Nitrile rubber (NBR), EPDM, Viton, or FKM |

Seal Type | Mechanical seal or packing seal |

Motor Type | Standard or explosion-proof motor |

Installation Orientation | Horizontal or vertical |

Power Supply | 220V / 380V / 440V, 50/60 Hz |

Drive Options | Gear motor, frequency converter, or variable speed drive |

The Single-Stage Dosing Screw Pump operates using the progressive cavity principle. It consists of a single helical rotor that turns inside a double-threaded stator. The interaction between the rotor and stator forms cavities that move progressively from the suction side to the discharge side as the rotor rotates.

This continuous cavity movement:

Transports the liquid smoothly and without pulsation.

Ensures accurate volumetric displacement per rotation.

Prevents backflow and pressure surges.

Allows precise control through speed variation (using VFD control).

Each rotation displaces a fixed volume of liquid, making it ideal for metering and proportional dosing tasks. By adjusting the motor speed, the operator can finely control the dosing rate with exceptional accuracy.

The Single-Stage Dosing Screw Pump finds extensive applications across a broad range of industries that require controlled, accurate, and reliable dosing performance.

Dosing of acids, alkalis, solvents, and catalysts

Feeding polymer solutions into reactors

Metering additives, emulsifiers, and surfactants

Handling corrosive liquids and process chemicals

Dosing coagulants and flocculants

Feeding lime slurry or polymer solutions

Sludge recirculation or chemical neutralization

Metering chlorine or pH control agents

Metering flavorings, syrups, and colorants

Controlled dosing of viscous ingredients like honey or cream

Handling yeast slurries and fermentation additives

Dosing liquid formulations and suspensions

Metering culture media and buffer solutions

Sterile liquid transfer in cleanroom environments

Metering dyes, bleaching agents, and sizing solutions

Feeding additives for paper coating lines

Dosing corrosion inhibitors, demulsifiers, and lubricants

Handling viscous drilling fluids and additives

Dosing of odor control chemicals

Feeding wastewater conditioning agents

Foundation and Alignment:

Install the pump on a stable, level foundation to minimize vibration. Ensure alignment between motor and pump coupling.

Piping Connections:

Suction and discharge piping should match pump port sizes.

Use flexible connectors to absorb vibration.

Ensure suction lines are airtight for efficient priming.

Electrical Wiring:

Confirm voltage and frequency compatibility.

For explosion-proof versions, ensure proper grounding and cable sealing.

Initial Priming:

Before first operation, fill the pump chamber with a small amount of liquid to avoid dry running.

Never start the pump dry — it can cause severe stator damage.

Open inlet and outlet valves fully.

Start the motor at low speed, gradually increasing to the desired flow rate.

Monitor discharge pressure, noise, and vibration during operation.

Use a variable frequency drive (VFD) to fine-tune dosing accuracy.

After use, flush the pump with clean water or solvent to remove residues.

Do not exceed rated pressure or temperature.

Ensure that seals and bearings are regularly inspected.

Avoid pumping liquids containing large solid particles unless equipped with pre-filtration.

Check and lubricate bearings regularly.

Replace stator and rotor components when wear affects flow accuracy.

Inspect the mechanical seal for leaks or friction wear.

Clean the pump internals after handling viscous or sticky fluids.

| Issue | Possible Cause | Solution |

Low or no flow | Air leak, clogged suction, worn rotor/stator | Tighten fittings, clean pipeline, replace components |

Excessive vibration | Misalignment, foreign particles | Realign motor, flush the system |

Leakage | Seal wear or improper installation | Replace or adjust mechanical seal |

Overheating | Dry running or excessive pressure | Ensure priming, reduce system pressure |

Noise during operation | Bearing failure or cavitation | Lubricate or replace bearings, check suction conditions |

High Metering Accuracy:

Capable of maintaining flow rate deviations within ±1% for precise dosing.

Wide Viscosity Range:

Handles liquids from low-viscosity chemicals to highly viscous pastes.

Stable Flow Delivery:

Provides continuous, non-pulsating flow ideal for sensitive processes.

Low Maintenance Design:

Simple assembly with easily replaceable parts reduces maintenance downtime.

Energy Efficiency:

Optimized screw geometry ensures maximum efficiency with minimal power input.

Compact and Versatile:

The single-stage design simplifies system integration into skid-mounted dosing units.

| Media Type | Recommended Material |

Water-based fluids | SS304 + NBR |

Acids and alkalis | SS316L + EPDM or FKM |

Solvents | SS316L + Viton |

Slurries | Hardened steel + NBR |

Food-grade applications | SS316L + Food-grade EPDM |

To enhance performance and accuracy, the Single-Stage Dosing Screw Pump can be equipped with automation systems such as:

Variable Frequency Drives (VFDs) for real-time flow control

Flow meters and pressure sensors for closed-loop feedback

PLC integration for automated dosing in industrial plants

Remote monitoring for maintenance alerts and data logging

This makes the pump ideal for modern smart dosing systems where precision and repeatability are essential.

Q1: What is the difference between a dosing screw pump and a standard screw pump?

A: The dosing screw pump is designed for small, controlled flow rates with enhanced accuracy and calibration features, ideal for metering and chemical dosing applications.

Q2: Can it handle viscous or abrasive media?

A: Yes, the pump can handle fluids up to 500,000 cP viscosity and even liquids containing small solid particles.

Q3: How is flow rate adjusted?

A: Flow rate can be precisely controlled by changing the motor speed through a frequency inverter or variable speed drive.

Q4: What’s the maximum discharge pressure?

A: Single-stage models typically handle up to 0.6 MPa; higher pressures require multi-stage configurations.

Q5: What are the typical maintenance intervals?

A: Inspection of seals and stator/rotor components every 6–12 months is recommended, depending on fluid characteristics.

Q6: Is it suitable for continuous operation?

A: Yes. The pump is designed for 24-hour continuous dosing in industrial systems.

Q7: Can it be used for food-grade dosing?

A: Absolutely. Using SS316L and food-grade stator materials, the pump meets hygiene requirements for food and beverage production.

Q8: What is the expected service life?

A: With proper maintenance, the rotor-stator set can last between 3,000–10,000 operating hours depending on media abrasiveness.

The Single-Stage Dosing Screw Pump offers a precise, efficient, and reliable solution for all dosing and metering requirements across industries. Its progressive cavity principle, smooth flow, and flexible control options make it ideal for both laboratory and large-scale industrial dosing applications.

Whether handling chemicals, sludge, food ingredients, or pharmaceutical liquids, this pump ensures consistent dosing accuracy, low maintenance, and long-term operational stability. With its compact structure, material adaptability, and automation compatibility, it’s a trusted choice for precision fluid management systems worldwide.

Copyright ? Jiangsu Longjie Pump Manufacturing Co., Ltd.