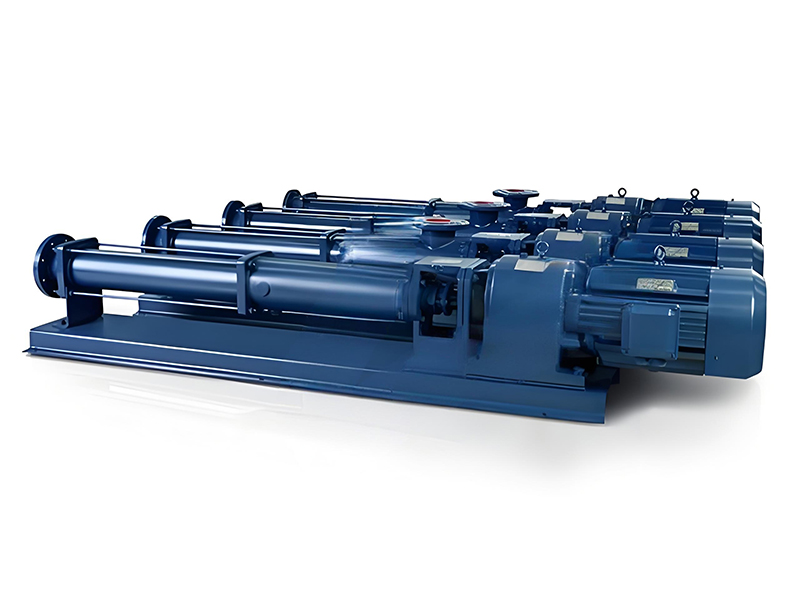

The Direct-Connected Single-Screw Pump is a compact, high-efficiency positive displacement pump that integrates the motor and pump body directly through a coupling connection, eliminating the need for an additional transmission mechanism such as a gearbox or belt drive. This design not only saves installation space but also enhances transmission efficiency, minimizes vibration, and reduces maintenance requirements.

As a type of Progressive cavity pump (PCP), the direct-connected single-screw pump delivers smooth, non-pulsating flow for handling a wide range of fluids — from low-viscosity liquids to high-viscosity pastes and slurries containing solid particles. The pump operates based on the interaction between a single helical rotor and a double-threaded elastomer stator, forming sealed cavities that transport fluid continuously from the suction to the discharge end.

Engineered for industrial reliability, low noise, and high volumetric efficiency, this pump is ideal for chemical processing, food production, wastewater treatment, oil transfer, and environmental engineering. Its modular structure allows easy integration into compact systems where space efficiency and reliable dosing or transfer are critical.

Direct Connection Design:

The pump and motor are directly coupled, eliminating mechanical transmission losses and improving overall efficiency by up to 10%.

Compact Structure:

Space-saving horizontal layout suitable for skid-mounted or mobile installations.

Low Pulsation Output:

Provides continuous, uniform flow without pressure surges, making it ideal for metering and dosing operations.

Wide Media Compatibility:

Handles liquids containing solids, fibers, or high viscosity, from sludge and slurry to oil and resin.

Corrosion-Resistant Materials:

Available in SS304, SS316L, or duplex stainless steel for aggressive or sanitary applications.

Low Shear and Gentle Handling:

Ensures safe transfer of shear-sensitive fluids such as emulsions, polymers, and biological liquids.

Easy Maintenance:

Fewer mechanical parts and modular components allow quick disassembly and low repair costs.

Energy Efficient:

Optimized rotor-stator geometry ensures consistent flow with lower power consumption.

| Parameter | Specification Range |

Model | Direct-Connected Single-Screw Pump |

Flow Rate | 0.1 – 60 m3/h |

Discharge Pressure | Up to 0.6 MPa (single stage) |

Suction Lift | Up to 8 meters |

Viscosity Handling | Up to 500,000 cP |

Operating Temperature | -20°C to +120°C (optional up to 180°C) |

Rotor Material | Stainless Steel 304/316L or Hard Chrome Plated Steel |

Stator Material | NBR, EPDM, Viton (FKM), or custom elastomers |

Pump Casing Material | Cast Iron, Carbon Steel, SS304, SS316L |

Seal Type | Mechanical Seal / Packing Seal |

Drive Type | Direct motor coupling (flange-connected) |

Installation Orientation | Horizontal or Vertical |

Power Supply | 220V / 380V / 440V, 50/60Hz |

Motor Type | Standard, Explosion-proof, or Variable Speed |

The direct coupling system ensures minimal energy loss and high transmission accuracy, making this model ideal for continuous 24-hour industrial service.

The Direct-Connected Single-Screw Pump operates on the progressive cavity principle. A single helical rotor rotates within a double-threaded stator made from elastic material. This forms cavities that progress from the suction side to the discharge end as the rotor turns.

The rotating motion creates continuous sealed chambers.

Each chamber moves the fluid forward without turbulence or pulsation.

Flow rate is directly proportional to rotation speed — allowing precise control.

Because of this design, the pump maintains constant flow at variable pressures, even with fluctuating inlet conditions. This ensures high metering precision, stable delivery, and protection of fluid properties.

The Direct-Connected Single-Screw Pump is highly versatile and widely used in industries where stable flow, low pulsation, and high viscosity handling are required.

Dosing acids, alkalis, resins, and solvents

Transferring emulsions, adhesives, and polymers

Pumping lubricants, oils, and fuel additives

Transferring sludge, lime slurry, and polymer solutions

Metering flocculants and coagulants

Handling biological sludge and thick effluent

Transferring sauces, creams, and syrups

Dosing yeast, chocolate, or fruit pulp

Handling viscous materials without damaging texture

Pumping coating materials, dyes, and starch

Feeding cellulose slurry and bleaching liquids

Transferring crude oil, drilling mud, and lubricants

Pumping abrasive mineral slurries

Handling dewatering and tailing operations

Pumping manure, digestate, or organic slurry

Feeding biogas reactors and digesters

Mount the pump on a stable foundation to minimize vibration.

Ensure correct motor-pump shaft alignment for smooth rotation.

Use flexible couplings to absorb operational shock.

The suction pipe should be as short and straight as possible to reduce suction losses.

For high-viscosity fluids, install the pump close to the fluid source.

Prime the pump before operation; never start the pump dry.

Check rotation direction — incorrect rotation may cause no flow or seal failure.

Open both suction and discharge valves.

Start the pump at low speed, gradually increasing to rated RPM.

Monitor suction pressure, discharge pressure, and motor current during startup.

Stop the motor and close the discharge valve slowly.

Flush the pump with water or solvent to remove residual media.

Disconnect power and drain remaining fluid if the pump will not be used for long periods.

Routine maintenance ensures long service life and consistent performance.

Weekly: Check for leaks, vibration, and noise.

Monthly: Inspect stator and rotor wear; check seal condition.

Quarterly: Lubricate bearings; verify motor alignment.

Annually: Replace worn stator, rotor, and seals as necessary.

Never allow the pump to run dry — this can permanently damage the stator.

Use OEM spare parts for replacement to maintain dimensional accuracy.

Keep suction lines clean and leak-free.

For abrasive media, use hardened rotors and wear-resistant stators.

Monitor energy consumption — rising current draw indicates internal wear.

| Problem | Possible Cause | Solution |

No flow or low output | Pump not primed, suction blockage, air leak | Re-prime, clean suction line, tighten fittings |

Excessive vibration | Misalignment or loose foundation | Realign motor and pump, tighten bolts |

Seal leakage | Worn mechanical seal or dry running | Replace seal, ensure proper lubrication |

Noise or cavitation | Suction lift too high or air ingress | Lower suction height, remove air pockets |

High power consumption | Overpressure, high viscosity, rotor-stator wear | Check pressure, reduce viscosity, replace components |

Overheating | Dry running or blocked discharge line | Stop immediately, clear blockage, refill with fluid |

| Fluid Type | Recommended Materials |

Water, wastewater | Cast Iron / SS304 + NBR |

Acidic/Caustic solutions | SS316L + EPDM/FKM |

Oils, fuels | SS304 + NBR |

Food and beverages | SS316L + Food-grade EPDM |

Abrasive slurries | Hardened Steel + NBR or EPDM |

For chemically aggressive fluids, use fluoroelastomer stators (Viton) and SS316L rotors to ensure corrosion resistance.

The direct-coupled design eliminates mechanical transmission losses, achieving up to 95% mechanical efficiency. Its progressive cavity structure provides steady flow with negligible pulsation — a key factor in dosing and metering systems.

By pairing the pump with a variable frequency drive (VFD), operators can achieve real-time flow control and energy savings of up to 20%. This makes the direct-connected single-screw pump ideal for both continuous and intermittent dosing applications.

| Aspect | Direct-Connected Screw Pump | Conventional Screw Pump (with gearbox) |

Transmission | Direct coupling | Belt or gear-driven |

Efficiency | Higher (less energy loss) | Moderate |

Space Requirement | Compact | Larger |

Maintenance | Low | Higher (more parts) |

Vibration & Noise | Low | Moderate |

Startup Time | Quick | Slower |

Overall Cost | Lower lifecycle cost | Higher due to gear wear |

The direct-connected single-screw pump supports full integration with:

PLC/DCS automation systems for process control

Flow and pressure sensors for automatic regulation

Variable-speed drives (VFDs) for dosing precision

Remote monitoring modules for predictive maintenance

This compatibility makes it suitable for modern industrial automation and smart fluid management systems.

Q1. What is the main advantage of a direct-connected screw pump?

A: It eliminates the gearbox or belt drive, resulting in higher efficiency, lower noise, and compact design.

Q2. Can it handle abrasive or viscous media?

A: Yes. The pump can handle slurries, oils, and viscous pastes with viscosities up to 500,000 cP.

Q3. What motor types are available?

A: Standard, explosion-proof, and variable-speed motors are all available for different environments.

Q4. How is the flow rate controlled?

A: By adjusting the motor speed manually or through a frequency inverter (VFD).

Q5. Is the pump suitable for food-grade applications?

A: Yes, with SS316L construction and food-grade elastomers, it meets hygienic standards.

Q6. What is the expected lifespan of the stator?

A: Typically 3,000–10,000 hours depending on fluid abrasiveness and operating conditions.

Q7. Can the pump run dry?

A: No. Dry running will cause stator damage; always ensure priming before operation.

Q8. Does it support horizontal and vertical installation?

A: Yes, it can be installed either horizontally or vertically according to site layout.

Copyright ? Jiangsu Longjie Pump Manufacturing Co., Ltd.