The sealing line and surface speeds are reduced by 20%, significantly extending service life compared to conventional geometry.

Even under wear, the conveying capacity and feed pressure remain stable over time.

The low working surface pressure is due to geometric changes in rotor diameter and eccentricity, which reduce axial forces on the joints and pump bearings.

With conventional geometric designs, axial forces can increase by up to 50%.

The extended geometry provides an optimized flow profile, thereby reducing equipment vibration.

The Long Lead Screw Pump is a specialized positive displacement pump designed for efficient transfer of highly viscous, abrasive, and particulate-laden fluids. Distinguished by its extended lead rotor, this pump delivers steady, non-pulsating flow over long distances and is ideal for applications requiring consistent metering, high pressure, or precise dosing.

Constructed from stainless steel or other corrosion-resistant alloys, the pump ensures durability, hygiene, and chemical resistance for demanding industrial processes. Its progressive cavity design makes it particularly suitable for heavy-duty fluid transfer, high-viscosity material handling, and challenging slurry applications.

The long lead screw pump features a single helical rotor with an extended pitch (lead), which allows for high-capacity transfer of viscous materials over longer distances compared to standard screw pumps. This design provides:

Increased flow per rotation

Reduced rotor speed for delicate fluids

High self-priming capacity

Continuous, pulsation-free flow

The rotor turns eccentrically inside a stationary stator, creating sealed cavities that move fluid from the suction side to the discharge side. This positive displacement mechanism ensures consistent flow regardless of fluid viscosity.

Pump Body (Casing):

Manufactured from stainless steel 304 or 316L, or other corrosion-resistant alloys. Designed to handle chemical, abrasive, or food-grade applications.

Rotor:

Long-lead helical rotor made from hardened stainless steel, optimized for smooth flow and high efficiency.

Stator:

Elastomeric lining made from NBR, EPDM, or FKM, compatible with a wide range of fluids and providing tight sealing and minimal backflow.

Drive Shaft and Bearings:

Heavy-duty bearings ensure stable rotation under high torque and viscous loading.

Mechanical Seal or Lip Seal:

Food-grade or industrial-grade seals prevent leakage and maintain hygiene standards.

Drive Unit:

Options include direct motor drive, gear reducer, or inverter-controlled drive for adjustable flow rates.

Mounting Options:

Horizontal, vertical, or portable mounting for flexibility in industrial setups.

The rotor rotates eccentrically within the stator, creating a series of sealed cavities. Each cavity moves fluid along the pump axis as the rotor turns. The long lead design increases flow per rotation, reducing rotor speed, which:

Minimizes shear on sensitive materials

Reduces wear and tear

Enables efficient high-viscosity fluid transfer

This principle allows the pump to handle slurries, pastes, sauces, adhesives, and food products with minimal product degradation.

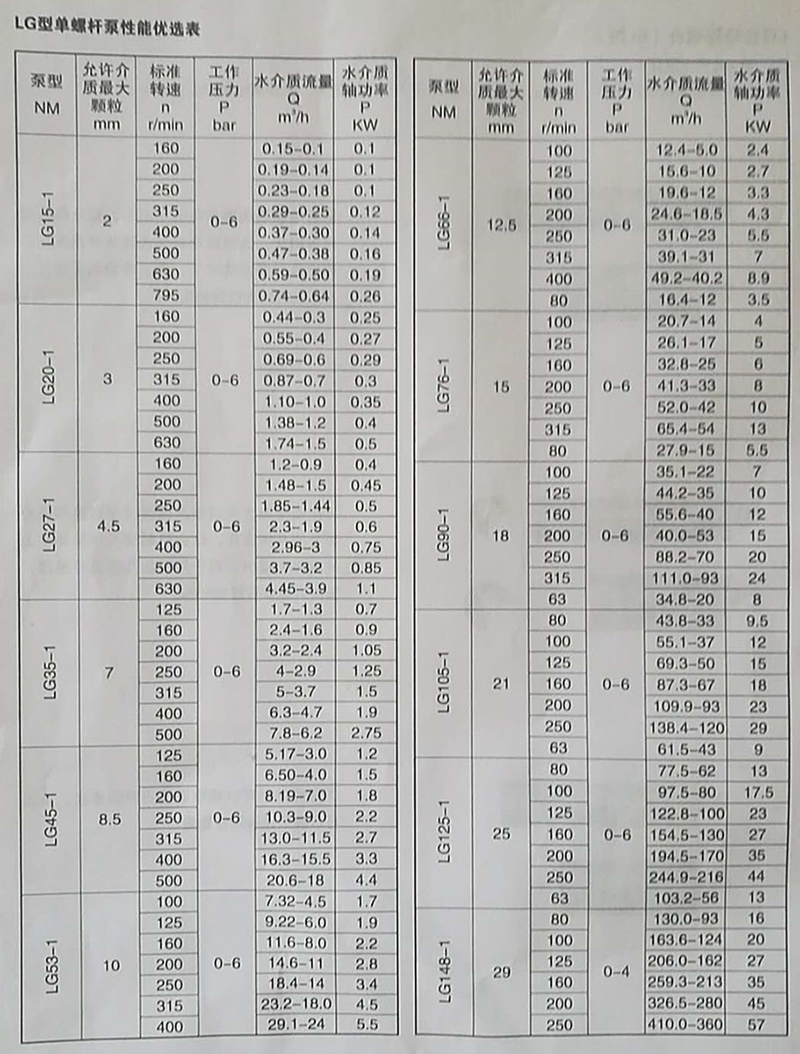

| Model | Flow Rate (m3/h) | Pressure (MPa) | Speed (rpm) | Viscosity (mPa·s) | Material | Temperature (°C) |

LLSP-10 | 1 – 5 | 0.6 | 200 – 600 | 1 – 50,000 | SS304 / NBR | -10 to 100 |

LLSP-25 | 3 – 12 | 0.6 | 150 – 500 | 1 – 100,000 | SS304 / EPDM | -10 to 120 |

LLSP-50 | 5 – 25 | 0.6 | 100 – 450 | 1 – 200,000 | SS316L / FKM | -10 to 150 |

LLSP-75 | 10 – 50 | 0.6 | 80 – 400 | 1 – 300,000 | SS316L / NBR | -10 to 150 |

Optional Configurations:

Heating jackets for temperature-sensitive fluids

Hopper feed for pastes and semi-solids

Variable frequency control for precise flow

High-pressure and long-distance transfer variants

High-Capacity Flow: Long lead rotor allows higher volume per rotation, ideal for large-scale processes.

Handles Viscous and Particulate Fluids: Capable of moving slurries, honey, adhesives, and other heavy materials.

Low Shear: Gentle flow preserves delicate structures in food and chemical products.

Pulsation-Free Operation: Stable, continuous flow ideal for metering, dosing, and filter press feeding.

Self-Priming: Capable of lifting fluid from empty suction lines or partially filled tanks.

Durable Construction: Stainless steel and elastomer components resist abrasion, corrosion, and wear.

Sanitary Options: Compliant with FDA, EHEDG, and 3A standards for food and pharmaceutical applications.

Flexible Mounting: Horizontal, vertical, and portable designs allow integration into various systems.

Energy-Efficient: Lower power consumption compared to high-speed centrifugal pumps for viscous fluids.

Copyright ? Jiangsu Longjie Pump Manufacturing Co., Ltd.