G-Type Sanitary Single Screw Pump

Sanitary Screw Pumps transport liquids of various viscosities, especially viscous and difficult-to-transport media.

1. Sanitary single screw pumps can transport liquids of various concentrations and separated, dehydrated dry materials.

2. Sanitary single screw pumps can transport liquids containing solid particles, fibers, and suspended matter.

3. Sanitary single screw pumps can transport mixtures of liquids, gases, and solids.

4. Sanitary single screw pumps can transport sensitive liquids that cannot withstand agitation, shearing, or erosion.

5. G-Type Sanitary Single Screw Pumps can transport corrosive liquids.

Main Applications of the G-Type Sanitary Screw Pump

Environmental Protection: Transporting industrial and domestic wastewater, sludge containing solid particles and short fibers, and particularly suitable for oil-water separators and plate-and-frame filter presses.

Food Industry: Transporting ketchup, mashed potatoes, peanut butter, yogurt, fresh cream, ice cream, cheese blocks, whey, beer, malt wort, yeast, fruit juice drinks, vegetable pastes, jams, jellies, etc.

Pharmaceutical Industry: Transporting various types of pill pastes, extracts, emulsifiers, biological products, cod liver oil, etc.

Daily Chemical Industry: Transporting shampoo, hand soap, toothpaste, cosmetics, soap, etc.

Paper Industry: Transporting glue, high-viscosity ink, wallpaper, PVC polymer plastic paste, and pulp of various concentrations and short fiber slurry.

Petroleum Industry: Transporting crude oil, crude oil-water mixtures, and coalfield gas-water mixtures. Construction Industry: Cement mortar, lime slurry, paint, and paste spraying; Mining Industry: Solid particles in mines, groundwater, and sewage slurry; Chemical Industry: Various suspensions, oils, greases, various colloid slurries, and various adhesives; Shipbuilding Industry: Wheel bottom cleaning, oil-water, oil residue, and oily wastewater conveying; Industrial boilers and power plants: Coal-water slurry conveying.

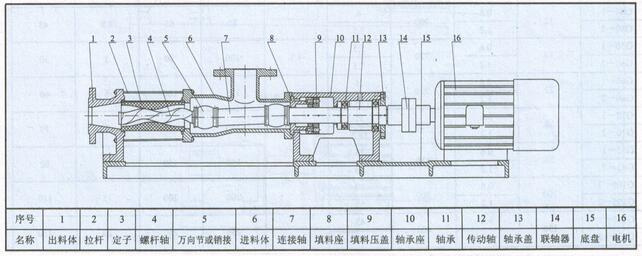

G type sanitary screw pump structure diagram

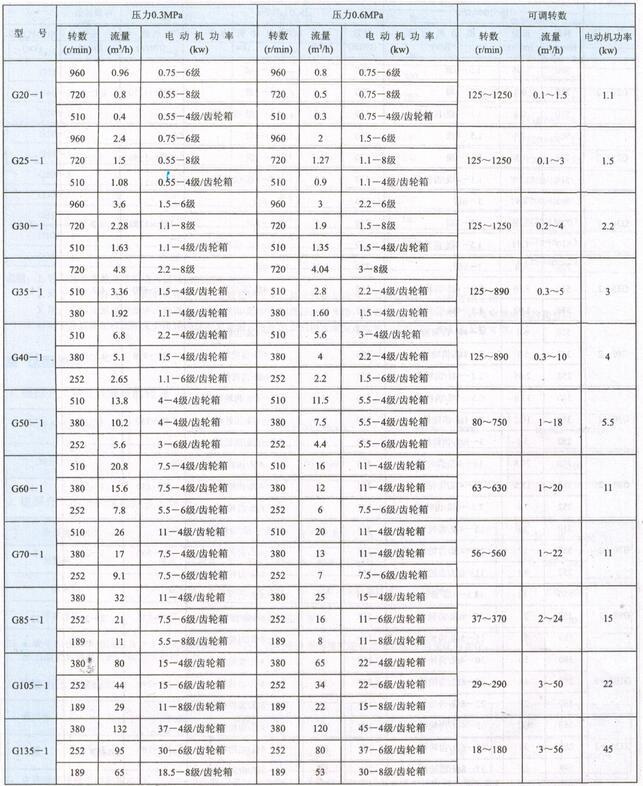

G type sanitary screw pump performance parameter table

The G-Type Sanitary Screw Pump is a high-performance, hygienic pump specifically designed for transferring viscous, shear-sensitive, and delicate materials in industries that demand precision, cleanliness, and reliability. Constructed from 316L stainless steel, this food-grade sanitary pump meets strict hygiene standards, making it ideal for the food, beverage, pharmaceutical, cosmetic, and chemical sectors.

With a single-screw or twin-screw configuration, the pump ensures gentle, continuous, and pulsation-free flow, preserving the integrity of sensitive fluids like chocolate, syrups, creams, lotions, and chemical solutions. Its seal-less or mechanical seal options prevent leakage, contamination, and downtime, providing a safe and reliable fluid transfer solution.

The compact and modular design allows easy integration into existing pipelines or processing lines, while its CIP/SIP cleaning compatibility ensures effortless maintenance and regulatory compliance. The G-Type Sanitary Screw Pump is ideal for applications where viscosity, shear sensitivity, and sanitary standards are critical.

The G-Type Sanitary Screw Pump is engineered to handle highly viscous fluids while maintaining hygiene and operational reliability. Its key specifications include:

| Parameter | Specification |

Pump Type | Single-screw / Twin-screw |

Material | 316L Stainless Steel |

Flow Rate | 0.1 – 50 m3/h |

Maximum Pressure | ≤ 1.2 MPa (12 bar) |

Maximum Temperature | 0 – 120°C |

Viscosity Range | ≤ 100,000 cP |

Inlet/Outlet | Sanitary tri-clamp or flange |

Seal Type | Seal-less or mechanical seal optional |

Motor Options | Electric, variable frequency, pneumatic |

Surface Finish | Ra ≤ 0.8 μm |

Cleaning | CIP/SIP compatible |

Flow Direction | Bi-directional capability |

These specifications allow the pump to transfer viscous materials such as chocolate, honey, creams, lotions, or resins efficiently and hygienically. Its modular rotor-stator design ensures minimal pulsation and shear, making it suitable for delicate materials where product integrity is critical.

The G-Type Sanitary Screw Pump is ideal for industries requiring precision, hygiene, and reliable viscous material transfer.

Chocolate, syrups, jams, and honey: Gentle transfer preserves product texture and taste.

Dairy products: Efficient pumping of milk, yogurt, cream, and other viscous dairy fluids.

Sauces and pastes: Maintains consistency and prevents aeration.

Injectable solutions and suspensions: Maintains sterility and precise dosing.

Creams, gels, and ointments: Shear-sensitive products remain undamaged during transfer.

Vaccines and biologics: Supports hygienic and contamination-free fluid movement.

Lotions, creams, gels, and oils: Smooth, continuous pumping ensures uniform product quality.

Shampoos and conditioners: Maintains viscosity and prevents foam formation.

High-viscosity personal care products: Efficient, sanitary transfer without product degradation.

Resins, adhesives, and polymers: Handles high-viscosity chemicals safely.

Acids and alkalis: 316L stainless steel construction ensures corrosion resistance.

Shear-sensitive formulations: Maintains material integrity during processing.

Pilot plants or laboratories: Accurate dosing and material transfer in small-scale production.

Automated filling systems: Hygienic and precise pumping for packaging lines.

To ensure maximum efficiency and long service life, follow these operational steps:

Positioning: Install horizontally or vertically, ensuring proper alignment with the piping system.

Connection: Use sanitary tri-clamps or flanges, tightened securely to prevent leaks.

Motor Alignment: Connect to the motor or drive system using flexible couplings to avoid misalignment.

Priming: Pre-fill the pump cavity for viscous materials or start at low speed to avoid dry running.

Start-Up: Gradually ramp up speed to ensure smooth priming.

Flow Adjustment: Use a variable frequency drive (VFD) to control flow rates.

Monitoring: Regularly check for unusual noise, vibration, or temperature increases.

Cleaning: Perform CIP/SIP cleaning cycles after each batch to maintain hygiene.

Routine Checks: Inspect seals, bearings, and rotors for wear.

Lubrication: Ensure drive system components are adequately lubricated.

Replacement Parts: Use OEM-certified parts for consistent performance.

Preventive Maintenance: Schedule periodic maintenance to avoid downtime.

It is ideal for viscous, shear-sensitive, or delicate fluids including honey, syrups, chocolate, creams, lotions, and chemical pastes. Maximum viscosity up to 100,000 cP.

Yes, the pump can operate with fluids up to 120°C. Higher temperature applications may require cooling jackets or special rotor materials.

The pump handles mildly abrasive materials. For highly abrasive fluids, abrasion-resistant rotors or stators are recommended.

Copyright ? Jiangsu Longjie Pump Manufacturing Co., Ltd.