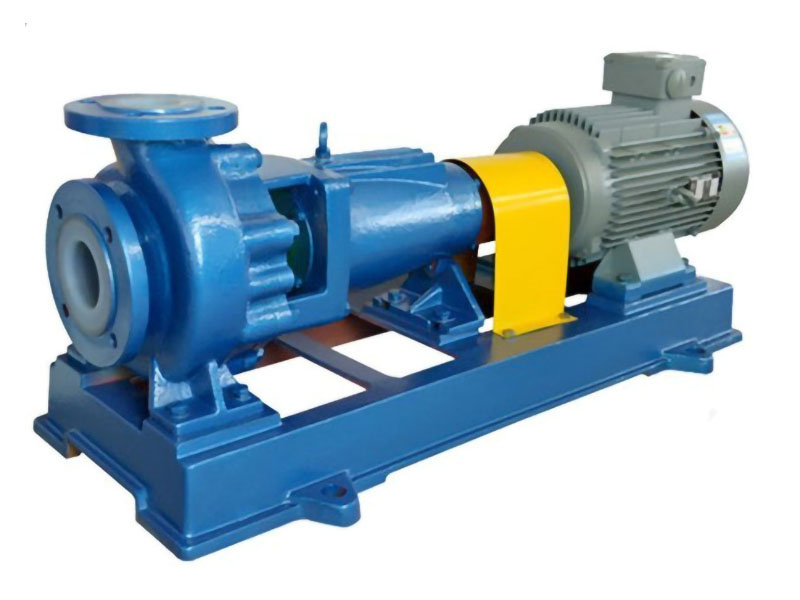

The CA Magnetic Drive Chemical Process Pump is a high-performance, seal-less centrifugal pump engineered for safe, leak-free transfer of corrosive, toxic, or hazardous chemicals in industrial applications. Utilizing magnetic drive technology, this pump eliminates traditional mechanical seals, packing, or gaskets, ensuring complete containment of pumped fluids and enhancing operator safety while reducing environmental risks.

Constructed with corrosion-resistant stainless steel (316L) and high-strength magnetic couplings, the CA Magnetic Pump is ideal for chemical processing, pharmaceutical production, food and beverage, semiconductor manufacturing, and laboratory applications. Its robust design allows continuous operation under demanding conditions while minimizing maintenance and operational downtime.

Unlike conventional pumps, the CA Magnetic Drive Pump transmits torque via a magnetic coupling, avoiding mechanical contact between the motor and impeller. This design ensures leak-free operation, vibration-free performance, and extended service life, even with aggressive or volatile chemicals.

With its modular design, high corrosion resistance, and versatility in handling low- to high-viscosity fluids, the CA pump is the preferred choice for industrial processes requiring chemical safety, product purity, and operational reliability.

Seal-Less Magnetic Drive

Eliminates mechanical seals and packing, preventing leaks.

Ideal for handling hazardous, corrosive, or toxic fluids.

Corrosion-Resistant Materials

Constructed from 316L stainless steel or optional Hastelloy C.

Resists chemical attack from acids, alkalis, solvents, and aggressive industrial fluids.

Fluoropolymer or PTFE Linings

Optional fluorine-lined wetted parts enhance chemical resistance.

Compatible with pH 0–14 for handling strong acids and alkalis.

High Efficiency

Optimized impeller and magnetic coupling reduce energy loss.

Smooth, vibration-free operation ensures consistent performance.

Wide Temperature and Pressure Range

Operates from -40°C to +150°C, with pressure ratings up to 10 bar for standard models.

High-pressure variants available for specialized applications.

Modular and Compact Design

Space-saving footprint for easy integration into existing pipelines or production lines.

Modular components allow simple maintenance, inspection, and replacement.

Versatile Fluid Handling

Handles viscous liquids, high-purity chemicals, acids, bases, solvents, and hazardous fluids.

Suitable for continuous, intermittent, or metering applications.

FDA and GMP Compliance

Optional food-grade and pharmaceutical variants meet strict hygiene and regulatory standards.

Low Maintenance and Long Life

Magnetic drive eliminates seal replacement, reducing downtime.

Durable construction ensures extended operational life in demanding chemical environments.

| Parameter | Specification Range |

Pump Type | Centrifugal, Magnetic Drive |

Flow Rate | 0.5 – 500 m3/h |

Head | 5 – 120 m |

Operating Temperature | -40°C to +150°C (dependent on materials) |

Pressure Rating | Up to 10 bar (standard), high-pressure variants up to 16 bar |

Material of Construction | 316L Stainless Steel, optional Hastelloy C, fluoropolymer linings |

Bearings | Anti-friction ceramic or PTFE bearings |

Seal Type | Seal-less, magnetic coupling drive |

Motor Options | IEC standard, VFD compatible, explosion-proof variants available |

Viscosity Range | Up to 1000 cP (depending on impeller and model) |

pH Range | 0–14 |

Connection Types | ANSI/DIN/JIS flanges, Tri-Clamp for sanitary applications |

Efficiency | Up to 85% hydraulic efficiency |

Noise Level | <65 dB(A) at full load |

Compliance | ISO 9001, CE, RoHS, FDA (food-grade models), GMP-compliant |

The CA pump is designed for chemical dosing, transfer, and circulation in environments handling strong acids, bases, solvents, and reactive chemicals. Its seal-less design prevents leakage, protecting operators and the environment.

Used in sterile fluid transfer and formulation, the CA Magnetic Pump ensures GMP-compliant, contamination-free operation. Suitable for high-purity liquids, sterile solutions, and continuous pharmaceutical production lines.

Optional food-grade models can safely pump acids, alkalis, syrups, oils, and viscous liquids. Stainless steel and fluoropolymer construction ensures hygiene compliance and easy cleaning.

The CA pump transfers high-purity acids and solvents used in semiconductor manufacturing, ensuring no contamination of wafers or critical components.

Ideal for small-scale chemical processes, laboratory experiments, and pilot production, offering precise, leak-free fluid handling.

The pump handles hazardous wastewater, acidic or alkaline effluents, providing environmentally safe and leak-free operation.

Suitable for hydrocarbons, solvents, and fuel additives, resistant to aggressive hydrocarbons, ensuring reliable continuous operation.

Handles corrosive brine, chemical additives, and acidic liquids safely, with construction materials resisting saltwater and harsh marine conditions.

Transfers gels, creams, and viscous cosmetic fluids without contamination or texture degradation.

Confirm pump and motor alignment.

Ensure the pump casing is filled with fluid to avoid dry running.

Verify electrical connections and correct voltage.

Inspect magnetic coupling and wetted parts for integrity.

Fill the pump casing completely with liquid.

Gradually start the motor to operational speed.

Observe for unusual vibration, noise, or heating.

Monitor flow rate and pressure to ensure proper operation.

Maintain fluid viscosity and temperature within recommended limits.

Use VFDs for precise control of flow and pressure.

Check magnetic coupling alignment and monitor pump performance periodically.

Gradually reduce motor speed.

Flush the pump with a compatible solvent if handling viscous or aggressive liquids.

Inspect bearings, impeller, and magnetic coupling after shutdown.

Visual Inspection

Inspect pump casing, impeller, and magnetic coupling for wear, corrosion, or damage.

Bearing Check

Replace bearings if unusual noise or vibration occurs.

Magnetic Coupling Maintenance

Inspect magnets for cracks, misalignment, or corrosion.

Ensure coupling gap meets manufacturer specifications.

Cleaning

Flush pump with a compatible solvent or cleaning solution after handling viscous or aggressive chemicals.

Periodic Overhaul

Recommended every 6–12 months depending on fluid type and operational frequency.

Inspect impeller, magnetic coupling, bearings, and wetted parts for wear.

Lubrication

Bearings are typically self-lubricated by pumped fluid; external lubrication is not required.

| Problem | Possible Cause | Solution |

Pump fails to deliver fluid | Air entrainment or dry running | Prime pump, ensure fluid presence |

Excessive vibration or noise | Bearing wear or misalignment | Replace bearings, realign pump and motor |

Reduced flow rate | Blocked impeller or high viscosity | Clean impeller, adjust fluid viscosity |

Magnetic coupling slippage | Misalignment or excessive gap | Adjust coupling gap, check alignment |

Fluid leakage at connections | Loose flanges or damaged seals | Tighten flanges, replace O-rings or gaskets |

Overheating | Low flow, high viscosity, or high ambient temperature | Increase flow, check viscosity and temperature |

Leak-Free Operation – Seal-less design eliminates fluid leakage risk.

Superior Corrosion Resistance – Stainless steel and optional fluoropolymer lining handle aggressive chemicals.

Durable and Reliable – Long operational life with minimal maintenance.

High Efficiency – Optimized impeller reduces energy consumption.

Versatile Applications – Chemical, pharmaceutical, food, semiconductor, cosmetic, and marine industries.

Safe and Hygienic – FDA and GMP compliant for food and pharmaceutical applications.

Compact and Modular Design – Simple installation, maintenance, and integration with pipelines.

The CA Magnetic Drive Chemical Process Pump is a reliable, durable, and versatile pump engineered for industries requiring leak-free, corrosion-resistant, and high-efficiency chemical transfer.

Copyright ? Jiangsu Longjie Pump Manufacturing Co., Ltd.